#scada applications

Explore tagged Tumblr posts

Text

customized scada applications

1 note

·

View note

Text

Industrial Alarm Management Application

#industrial reporting solution#industrial reporting software#industrial reports development company#reporting tool for industrial automation#reporting software for industrial automation#Scada reporting software#report generation in Scada#best reporting software#Scada report generation#best reporting tools#industrial automation reporting tool#reporting tool for Scada#web based reporting tools#web based reporting software#automated reporting and data analysis software#Batch Reporting Application#Data Log Reporting Application#MKT Analysis#MKT Analysis reports development#Market Analysis application#Alarm Reporting Application

0 notes

Text

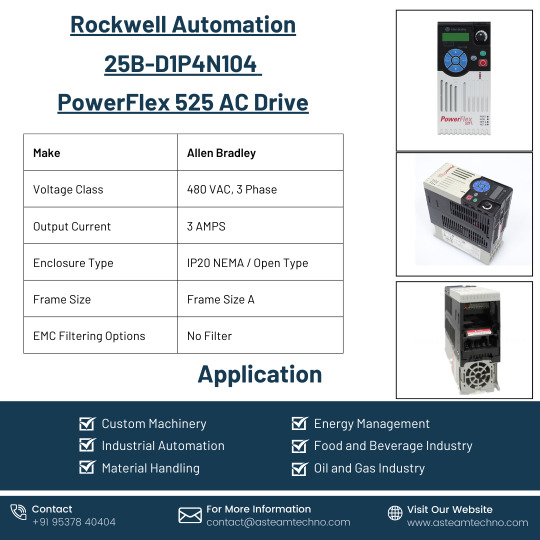

Rockwell Automation 25B-D1P4N104

The Rockwell Automation 25B-D1P4N104 is a part number for a specific variable frequency drive (VFD) within the Allen-Bradley PowerFlex 525 series. The PowerFlex 525 is a compact, versatile, and cost-effective drive designed to control motors in a wide range of industrial applications.

#automation#trending#tumblr trends#viralpost#viral#bestdeals#trendingnow#allen bradley#rockwell automation#plc#SCADA#HMI#powerflex525#application#technical#development#engineering#programs

1 note

·

View note

Text

Looking for the Best Automation Solution In Zirakpur. Our company stands as a leading project expert in Electrical, IoT, SCADA, Artificial Intelligence, Automation Solution, and Instrumentation. We specialize in delivering cutting-edge, customized automation solutions to optimize business operations. With a commitment to innovation and excellence, we provide the best automation systems in Zirakpur, ensuring efficiency, scalability, and long-term success for our clients.

1 note

·

View note

Text

BLIIoT 4G SMS Remote Monitoring Alarm Controller S272 for Aquaculture Monitoring

Foreword

Aquaculture is an important agricultural industry, and real-time monitoring of water quality parameters is critical to the success of farming

Remote Monitoring RTU 271 Functions

Remote Monitoring RTU 271 have 8 digital inputs, 6 analog or PT100 resistance temperature detector (RTD) inputs, 4 relay outputs, 1 environmental sensor input for monitoring site temperature and humidity, and an RS485 serial port. It can automatically monitor and operate I/O ports through SMS, cloud platform, web server, Internet, timer and programmed interlocking events.

Solution Requirements

Real-time monitoring of water quality parameters such as PH value and conductivity of water bodies. Users can remotely see the water quality conditions in real time through mobile phones and computers. When PH value, conductivity, dissolved oxygen and other parameters exceed the limits, users will be notified through SMS, phone calls, WeChat, emails, etc.

Solution Introduction

Remote Monitoring RTU S272 transmits data to the cloud for data processing through a wired connection with the PH sensor. The cloud feeds the data back to the cloud platform. Users can obtain PH value, conductivity, redox potential, and dissolved oxygen through the mobile APP computer web page. and other status; when the relevant parameters of water quality exceed the limit, the alarm information will be notified to the personnel on duty through text messages, phone calls, WeChat, etc. When necessary, equipment such as acid adding pumps or alkali adding pumps can be directly controlled through the cloud platform

Solution Advantages

1. Data Collection and Analysis

Remote Monitoring RTU S272 supports 4G transmission without distance restrictions, can monitor water quality parameters in real time, record data, perform historical data analysis, and provide visual reports so that farmers can better understand water quality conditions.

2.Real-time Monitoring

Monitor on-site water quality status 24 hours a day through mobile phones and computers; provide a solution for real-time monitoring of water quality parameters, remote access and alarm notification for the aquaculture industry

3. Alarm and Notification System

The system can set thresholds for water quality parameters. Once the parameters exceed the limits, users will be notified through multiple notification channels (SMS, phone calls, WeChat, and emails) so that they can take timely measures.

4. Remote Access and Control

Through mobile phones, computers and other devices, users can remotely access monitoring data at any time and even perform remote control to adjust water conditions.

5. Results and Benefits

By using Remote Monitoring RTU S272, the aquaculture industry can monitor water quality parameters in real time, obtain timely alerts and remote control, improve breeding efficiency, reduce losses, and achieve greater economic benefits.

Summarize

Remote Monitoring RTU S272 brings innovative solutions to the aquaculture industry, helping farmers achieve real-time water quality monitoring, alarm notification and remote control, thereby improving the efficiency of aquaculture, ensuring the healthy growth of organisms, and creating greater value.

More information about BLIIoT 4G SMS Remote Monitoring Alarm Controller S272: https://www.bliiot.com/m2m-rtu-p00174p1.html

#iot#iotsolution#smartaquaculture#remotemonitoring#remotecontrol#alarm#controller#rtu#gateway#iomodule#sms#4g#rs485#modbus#mqtt#scada#alibabacloud#huaweicloud#BLIIoT#BLIIoT Applications

0 notes

Text

Battery-operated Remote Terminal Units Market Research, Size, Share, Analysis, Overview and Regional Outlook Study 2017 – 2032

The market for Remote Terminal Units (RTUs) that are battery-operated allows them to function in isolated or off-grid regions where access to a reliable power supply is restricted. RTUs are electronic devices used to monitor and manage remote equipment and processes in many different industries, such as oil and gas, water and wastewater management, power distribution, and telecommunications. Here is a summary of the market for battery-operated RTUs, including information on demand:

Market Overview: Due to a number of circumstances, the market for battery-operated RTUs has been expanding. The need for battery-operated RTUs has been fueled by the necessity for remote monitoring and control capabilities in various industries, particularly in places with weak power infrastructure. These devices enable efficient monitoring and control of remote assets without the requirement for a continual external power source thanks to their dependable and autonomous operation.

Demand Drivers:

1. Real-time monitoring and control of assets: situated in remote or isolating locations are necessary in many businesses. Without the requirement for a sizable power infrastructure or reliance on cable connections, battery-operated RTUs allow for effective data gathering, monitoring, and control of these assets.

2. Applications Off-Grid: In off-grid applications where access to a dependable power supply is restricted or nonexistent, battery-operated RTUs are widely used. Examples include remote water pumping stations in rural areas, environmental monitoring stations, remote weather monitoring stations, and remote oil and gas wellheads.

3. Emergency and Temporary Installations: Whereas immediate deployment is necessary, battery-powered RTUs are also used in emergency and temporary installations. When catastrophe recovery, building projects, or temporary infrastructure installations are taking place, these machines can instantly provide remote monitoring and control capabilities.

4. Environmental Monitoring: Data collection from remote weather stations, air quality sensors, and water quality sensors are all important aspects of environmental monitoring that battery-operated RTUs play a key role in. Continuous monitoring is made possible in remote or environmentally delicate locations by these equipment.

5. IoT Connectivity: The need for battery-operated RTUs has increased as the Internet of Things (IoT) is becoming more widely used in a variety of businesses. These devices are essential parts of IoT networks because they provide seamless data transmission, communication, and control between remote assets and central management systems.

Here are some of the key benefits for Stakeholders:

Remote Monitoring and Control

Flexibility and Mobility

Cost-Effective Deployment

Resilience to Power Outages

Integration with IoT and Smart Grids

Increased Data Accessibility

Environmental Monitoring and Compliance

Rapid Deployment for Emergency Response

Redundancy and Reliability

Scalability and Future-Proofing

We recommend referring our Stringent datalytics firm, industry publications, and websites that specialize in providing market reports. These sources often offer comprehensive analysis, market trends, growth forecasts, competitive landscape, and other valuable insights into this market.

By visiting our website or contacting us directly, you can explore the availability of specific reports related to this market. These reports often require a purchase or subscription, but we provide comprehensive and in-depth information that can be valuable for businesses, investors, and individuals interested in this market.

“Remember to look for recent reports to ensure you have the most current and relevant information.”

Click Here, To Get Free Sample Report: https://stringentdatalytics.com/sample-request/battery-operated-remote-terminal-units-market/10333/

Market Segmentations:

Global Battery-operated Remote Terminal Units Market: By Company • SIEMENS • SENECA • Omniflex • King Pigeon Communication Co.,Limited • Servelec Group • TEKBOX • Micro Sensor Co., Ltd. • Hitachi Group • Remsdaq Ltd Global Battery-operated Remote Terminal Units Market: By Type • GPRS • GSM • Modular • Others Global Battery-operated Remote Terminal Units Market: By Application • Power Industry • Government and Utilities • Industrial Global Battery-operated Remote Terminal Units Market: Regional Analysis The regional analysis of the global Battery-operated Remote Terminal Units market provides insights into the market's performance across different regions of the world. The analysis is based on recent and future trends and includes market forecast for the prediction period. The countries covered in the regional analysis of the Battery-operated Remote Terminal Units market report are as follows: North America: The North America region includes the U.S., Canada, and Mexico. The U.S. is the largest market for Battery-operated Remote Terminal Units in this region, followed by Canada and Mexico. The market growth in this region is primarily driven by the presence of key market players and the increasing demand for the product. Europe: The Europe region includes Germany, France, U.K., Russia, Italy, Spain, Turkey, Netherlands, Switzerland, Belgium, and Rest of Europe. Germany is the largest market for Battery-operated Remote Terminal Units in this region, followed by the U.K. and France. The market growth in this region is driven by the increasing demand for the product in the automotive and aerospace sectors. Asia-Pacific: TheAsia-Pacific region includes Singapore, Malaysia, Australia, Thailand, Indonesia, Philippines, China, Japan, India, South Korea, and Rest of Asia-Pacific. China is the largest market for Battery-operated Remote Terminal Units in this region, followed by Japan and India. The market growth in this region is driven by the increasing adoption of the product in various end-use industries, such as automotive, aerospace, and construction. Middle East and Africa: The Middle East and Africa region includes Saudi Arabia, U.A.E, South Africa, Egypt, Israel, and Rest of Middle East and Africa. The market growth in this region is driven by the increasing demand for the product in the aerospace and defense sectors. South America: The South America region includes Argentina, Brazil, and Rest of South America. Brazil is the largest market for Battery-operated Remote Terminal Units in this region, followed by Argentina. The market growth in this region is primarily driven by the increasing demand for the product in the automotive sector.

Visit Report Page for More Details: https://stringentdatalytics.com/reports/battery-operated-remote-terminal-units-market/10333/

Reasons to Purchase Battery-operated Remote Terminal Units Market Report:

• To obtain insights into industry trends and dynamics, including market size, growth rates, and important factors and difficulties. This study offers insightful information on these topics.

• To identify important participants and rivals: This research studies can assist companies in identifying key participants and rivals in their sector, along with their market share, business plans, and strengths and weaknesses.

• To comprehend consumer behaviour: these research studies can offer insightful information about customer behaviour, including preferences, spending patterns, and demographics.

• To assess market opportunities: These research studies can aid companies in assessing market chances, such as prospective new goods or services, fresh markets, and new trends.

In general, market research studies offer companies and organisations useful data that can aid in making decisions and maintaining competitiveness in their industry. They can offer a strong basis for decision-making, strategy formulation, and company planning.

About US:

Stringent Datalytics offers both custom and syndicated market research reports. Custom market research reports are tailored to a specific client's needs and requirements. These reports provide unique insights into a particular industry or market segment and can help businesses make informed decisions about their strategies and operations.

Syndicated market research reports, on the other hand, are pre-existing reports that are available for purchase by multiple clients. These reports are often produced on a regular basis, such as annually or quarterly, and cover a broad range of industries and market segments. Syndicated reports provide clients with insights into industry trends, market sizes, and competitive landscapes. By offering both custom and syndicated reports, Stringent Datalytics can provide clients with a range of market research solutions that can be customized to their specific needs

Contact US:

Stringent Datalytics

Contact No - +1 346 666 6655

Email Id - [email protected]

Web - https://stringentdatalytics.com/

#Battery-operated Remote Terminal Units#RTU Market#Remote Monitoring#Wireless RTU#Industrial Automation#Battery-powered RTU#IoT (Internet of Things)#Energy Efficiency#Data Collection#Telemetry#Remote Control#Battery-powered Sensors#SCADA (Supervisory Control and Data Acquisition)#Energy Management#Off-grid Applications#Renewable Energy#Battery Technology#Remote Sensing#Communication Protocols#Edge Computing#Connectivity Solutions#Remote Data Acquisition#Condition Monitoring#Asset Management.

0 notes

Text

The Difference Between Low, Medium, and High Voltage Switchgear

Switchgear plays a critical role in the generation, transmission, and distribution of electrical power. It ensures safe and efficient operation by controlling, protecting, and isolating electrical circuits and equipment. But not all switchgear is created equal — low, medium, and high voltage switchgear are designed for different voltage levels and applications.

Understanding the differences between these types is crucial for electrical engineers, electricians, project managers, and anyone involved in power systems. In this article, we break down what sets them apart in terms of voltage range, components, applications, design, and safety considerations.

What is Switchgear?

Before diving into the differences, let’s clarify what switchgear is.

Switchgear refers to the combination of electrical disconnect switches, fuses, or circuit breakers used to control, protect, and isolate electrical equipment. It is essential for de-energizing equipment for maintenance and for clearing faults in the power system.

Classification by Voltage Level

Low Voltage Switchgear (LV)

Voltage Range:

Up to 1,000V AC (typically 400V/690V in 3-phase systems)

Key Components:

Miniature Circuit Breakers (MCBs)

Molded Case Circuit Breakers (MCCBs)

Residual Current Devices (RCDs)

Contactors and relays

Busbars, metering, control panels

Applications:

Residential and commercial buildings

Data centers and office spaces

Light industrial automation

Control panels and motor control centers (MCCs)

Characteristics:

Compact and easy to install

High frequency of operation

Relatively simple maintenance

Often enclosed in modular panels

Standards:

IEC 61439

NEC (National Electrical Code)

Medium Voltage Switchgear (MV)

Voltage Range:

1kV to 36kV (sometimes up to 72.5kV)

Key Components:

Vacuum circuit breakers (VCBs)

SF₆ (sulfur hexafluoride) insulated switchgear

Current and voltage transformers (CTs, VTs)

Protective relays

Grounding switches

Applications:

Electrical substations

Large factories and industrial plants

Railways and airports

Renewable energy farms (wind/solar)

Characteristics:

Higher insulation and safety requirements

More robust protection systems

Often installed indoors or in compact outdoor enclosures

May use gas-insulated or air-insulated designs

Standards:

IEC 62271–200

IEEE C37 series

High Voltage Switchgear (HV)

Voltage Range:

Above 36kV (commonly 66kV, 132kV, 220kV, up to 765kV)

Key Components:

SF₆ circuit breakers

Air blast or oil circuit breakers (older systems)

Gas-insulated switchgear (GIS)

Disconnectors and earthing switches

High-end protection relays and SCADA integration

Applications:

National and regional power transmission networks

Power generation plants

Interconnecting large substations

Critical infrastructure (e.g., large data centers, airports)

Characteristics:

Complex installation and high-cost infrastructure

Requires rigorous safety procedures and specialized training

Often installed outdoors or in GIS (Gas Insulated Switchgear) format

Includes extensive monitoring and automation

Standards:

IEC 62271–100 (HV circuit breakers)

IEEE C37.06

ANSI C37 series

Safety Considerations

Always follow local electrical codes, use personal protective equipment (PPE), and conduct routine maintenance regardless of switchgear type.

Conclusion

Choosing the right switchgear type is critical for ensuring safe and efficient power distribution. Whether you’re designing a residential panel or a high-voltage substation, knowing the difference between low, medium, and high voltage switchgear helps you make informed decisions about equipment, safety, and performance.

Mastering this knowledge isn’t just good practice — it’s essential for anyone serious about a career in the electrical field.

6 notes

·

View notes

Text

A Comprehensive Guide to Power Systems Protection for Engineers

Introduction:

Power systems protection is a critical aspect of electrical engineering that focuses on safeguarding electrical equipment, personnel, and the power grid from faults, failures, and abnormal operating conditions. This comprehensive guide aims to provide engineers with valuable insights into key principles, techniques, and best practices in power systems protection.

1. Understanding System Operation and Fault Types:

Before delving into protection strategies, it is essential to have a solid understanding of how power systems operates and the various types of faults that can occur. This includes studying system components, such as generators, transformers, transmission lines, circuit breakers, relays, and protective devices. Familiarity with fault types like short circuits, open circuits, ground faults, and transient overvoltages is crucial as a foundation.

2. Principles of Protection Coordination:

Effective power systems protection requires proper coordination among protective devices. Engineers must understand the concept of selectivity to ensure that only the device closest to a fault operates, minimizing disruption to the rest of the system. Proper coordination involves selecting appropriate current settings, time delays, and coordination curves for relays and circuit breakers.

3. Relay Device Fundamentals:

Relays are an integral part of power systems protection, serving as the first line of defense against electrical faults. Engineers should have a thorough knowledge of different relay types, including overcurrent relays, differential relays, distance relays, and directional relays. Understanding their operating principles, features, and limitations aids in choosing the most suitable relays for specific applications.

4. Protective Device Coordination:

Coordinating protective devices within a system is critical to maintaining stability and preventing cascading failures during faults. Engineers must carefully analyze and design protection schemes that consider factors such as fault impedance, fault currents, relay response characteristics, and coordination margins. Advanced techniques like time grading and impedance grading can be employed to achieve optimal coordination.

5. Fault Analysis and System Modeling:

Performing fault analysis and system modeling helps engineers gain insights into power flow, fault currents, voltage profiles, and system stability. Engineers must be proficient in using software tools like ETAP, PSCAD, and DSA Tools to accurately simulate fault scenarios and assess the performance of protection schemes. Detailed knowledge of system modeling techniques enables engineers to make informed decisions regarding relay settings and coordination.

6. Communication-Based Protection:

With the increasing complexity of modern power systems, communication-based protection plays a crucial role in maintaining reliability. Knowledge of communication protocols such as IEC 61850, GOOSE (Generic Object-Oriented Substation Event), and SCADA (Supervisory Control and Data Acquisition) systems is essential for engineers to design and implement advanced protection solutions that utilize real-time data exchange between substations and control centers.

7. Integration of Automation and Control Systems:

Incorporating automation and control systems into power systems protection enhances operational efficiency and reduces response time during faults. Engineers need to understand concepts like remote terminal units (RTUs), programmable logic controllers (PLCs), and human-machine interfaces (HMIs). Familiarity with protocols like Modbus, DNP3 (Distributed Network Protocol), and OPC (OLE for Process Control) enables seamless integration of protection systems with wider control infrastructure.

8. Commissioning, Testing, and Maintenance:

Implementing effective protection strategies requires thorough commissioning, testing, and maintenance procedures. Engineers should be well-versed in practices like primary injection testing, secondary injection testing, relay calibration, fault simulation, and periodic inspections. Adhering to manufacturer guidelines, industry standards, and safety protocols ensures equipment reliability and optimal performance.

9. Access to Resources and Industry Awareness:

Staying connected with organizations like the IEEE (Institute of Electrical and Electronics Engineers) and IET (Institution of Engineering and Technology) is crucial for access to valuable resources. Engineers should actively seek research papers, technical articles, conferences, and networking opportunities. Staying informed about relay technology advancements from prominent manufacturers aids in adopting the latest protection techniques.

10. Software Applications for Enhanced Protection:

Utilizing software applications is vital in power systems protection. Advanced tools like ETAP, PSCAD, and DSA Tools aid in relay coordination analysis, fault simulation, and system modeling. Acquiring proficiency in these common industry software packages enables engineers to design and optimize protection schemes effectively.

11. Compliance with Local National Codes:

Adhering to local national codes and regulations is paramount in power systems protection. Understanding and implementing specific electrical codes and standards relevant to the country of operation is crucial. Compliance ensures safe and reliable system design, installation, and operation aligned with legal requirements and best practices.

Conclusion:

By encompassing the principles, techniques, and best practices discussed in this guide, engineers pursuing careers in power systems protection can develop a strong foundation. Continuous learning, staying updated on industry advancements, and compliance with local national codes will ensure engineers can design, implement, and maintain robust and reliable protection schemes for the power grid and its critical assets.

The Author Biography: Qusi Alqarqaz

Qusi Alqarqaz is an experienced professional in power system protection, specializing in sharing knowledge and guiding young engineers. With a career spanning utility and oil and gas industries in Texas, New Mexico, and Qatar, he has amassed extensive industry experience.

Collaborating with leading manufacturers such as SEL, ABB, Siemens, Schneider, among others, Qusi has gained proficiency in a range of protective relays. He actively pursues continuing education, completing professional development courses with software providers including ETAP and Milsoft, enabling him to utilize advanced tools for power system analysis and protection design.

Qusi's dedication to staying up-to-date with industry advancements led him to pursue additional training. He completed professional development courses at Wisconsin University, equipping him with specialized knowledge crucial for working with high-voltage power systems. He also studied power generation extensively at Strathclyde University in the UK.

Qusi actively shares his knowledge through collaborating on large-scale projects and providing training sessions for professionals. Through his posts, he aims to offer guidance and mentorship for young engineers in power system protection. His practical advice and personal experiences will empower the next generation of experts in this field.

Contact the Author:

Qusi actively shares his knowledge through collaborating on large-scale projects and providing training sessions for professionals.

Qusi Alqarqaz

9 notes

·

View notes

Text

"One Institute, Many Opportunities:

Build Your Skills in Marketing, Automation, and AI"

In a world where data and technology rule, upskilling has become crucial for success in contemporary sectors. The chance to learn in-demand skills is now more accessible than ever for professionals and students in Kannur, Kerala. There are currently universities in Kannur that provide state-of-the-art instruction in a variety of fields, whether you want to work as a certified industrial automation engineer, a data scientist, or a digital marketing strategist.

IPCS

The industry-focused courses offered by IPCS Global Kannur, a top technical training center in Kerala, include Digital Marketing, Industrial Automation, BMS (Building Management Systems), CCTV & Security Systems, Python Programming, and Data Science. IPCS Global places a strong emphasis on practical instruction and real-world application to close the knowledge gap between academia and industry demands. With its state-of-the-art laboratories and knowledgeable instructors, the Kannur Center guarantees that students get both academic and real-world experience. With flexible learning options, globally recognized certifications, and committed placement support, IPCS Global Kannur can help you thrive in today's competitive job market, whether you're a professional looking to advance your skills or a student ready to start a career.

Digital Marketing

Every facet of lead generation and online brand creation is covered in the Digital Marketing program.Explore the realms of social media tactics, content marketing, SEO, Google Ads, online branding, and more. With training in real-time projects, campaign management, and analytics tools, our Digital Marketing course is intended to prepare you for the workforce.

What Is Digital Marketing and Why Does It Matter Today?

Businesses can no longer rely exclusively on traditional marketing strategies in the fast-paced, internet-driven world of today. Regardless of your company's size—startup, small, or multinational—your internet presence has the power to create or break your success. Digital marketing is a potent tool for connecting with your audience, building your brand, and achieving results.

What You’ll Learn:

Search Engine Optimization (SEO)

Google Ads & Analytics

Social Media Marketing (SMM)

Content Creation & Strategy

Email & Affiliate Marketing

What Makes Digital Marketing Vital?

Greater Reach

Digital marketing, as opposed to traditional marketing, enables instantaneous worldwide audience reach.

Economical

Online marketing are frequently more measurable and less expensive than print or television advertisements.

Measurable Outcomes

You can make data-driven decisions and monitor performance in real time with tools like Facebook Insights and Google Analytics.

Advertising That Is Targeted

Your ROI can be raised by targeting users according to their location, age, hobbies, behavior, and more.

Enhances Brand Image

Credibility and trust are increased by having a strong online presence. This is influenced by social proof, reviews, and interesting content.

Industrial Automation

From PLC programming to SCADA systems, our Industrial Automation course equips you with the skills needed in the manufacturing, robotics, and process control sectors. See the newest tools and simulations up close.

Speed, accuracy, and efficiency are no more optional in the cutthroat industrial environment of today; they are necessary. Industrial automation is a solution to the problem. Automation is changing how businesses function, from power generation and food packaging to automobile factories, making operations more dependable, intelligent, and safe.

What is Industrial Automation?

Industrial automation is the act of running machinery and processes with little assistance from humans by using control systems like computers, robots, and programmable logic controllers (PLCs). Intelligent systems that are capable of real-time monitoring, control, and optimization of industrial procedures take the place of manual operations.

Key Highlights:

PLC & HMI Programming

SCADA Integration

Electrical & Pneumatic Control Systems

Industrial Sensors & Actuators

BMS (Building Management Systems)

Take control of the clever brain that powers smart buildings! Learn how to manage and keep an eye on energy, fire, lighting, and HVAC systems. Our BMS training can help you become ready for careers in smart infrastructure deployment and facilities management.

The requirement for integrated control and monitoring systems grows as buildings become smarter and more energy-efficient. In order to manage a building's vital services for sustainability, efficiency, and safety, BMS (Building Management Systems) are crucial.

Covered Topics:

HVAC Controls & Integration

Lighting & Access Control

Energy Monitoring

Fire Alarm & Security Systems

CCTV & Surveillance Systems

CCTV installation and maintenance are essential skills given the rising demand for security systems. The technical know-how from system design to installation and remote monitoring is taught in our course.

Course Modules:

Camera Types & Configuration

DVR/NVR Setup

IP vs Analog Systems

Troubleshooting & Maintenance

Python Programming

Learn Python from the ground up—it's perfect for both novices and developers. You will acquire the coding abilities required for automation, web development, and data science through hands-on examples and real-world applications.

One of the most important skills you may have in the digital age is the ability to understand and use data. Whether it is through AI models, consumer behavior analysis, or market trend prediction, data science is revolutionizing every organization. Python, one of the most powerful yet user-friendly programming languages, is at the center of this change.

The goal of data science is to extract meaningful insights from massive volumes of both structured and unstructured data. Combining elements of statistics, machine learning, programming, and data visualization, it resolves complex problems and facilitates decision-making.

Learn To:

Write Efficient Python Code

Build Web Applications

Automate Tasks

Handle File and Data Operations

Data Science

Our Data Science program teaches you how to glean valuable insights from data, which is the new oil. Use Python and industry-standard tools to study data visualization, machine learning, and statistics.

Why Choose IPCS GLOBAL

Experienced Industry Trainers

100% Practical-Oriented Training

Certification Support

Placement Assistance

Flexible Batches (Online & Offline)

CONCLUSION

Whether you're stepping into the world of Industrial Automation, diving into the digital landscape with Digital Marketing, managing smart buildings with BMS, or unlocking the power of Python and Data Science, our hands-on, industry-driven training programs are designed to make you job-ready and future-proof.

With expert instructors, real-time project experience, and strong placement support, IPCS has become a trusted name for quality technical education and professional growth. Join us today and take the first step toward a brighter, smarter future.

Start Your Today!

📞 Call us: 9745396641

🌐 E MAIL ID:[email protected]

Visit website:ipcs

0 notes

Text

Best Quality Distillery plant manufacturer

Choosing the Best Quality Distillery Plant Manufacturer: A Look at Rattan Industri

In the competitive world of alcohol production, the quality of distillery plants plays a critical role in determining operational efficiency, product quality, and long-term profitability. As the demand for high-quality ethanol and spirits continues to rise globally, selecting the right distillery plant manufacturer is more important than ever. Among the leading names in this field, Rattan Industri has emerged as a trusted manufacturer, known for delivering advanced, reliable, and efficient distillation systems.

The Importance of Quality in Distillery Plants

Distillery plants are complex systems that require precision engineering, robust materials, and intelligent automation. From fermentation to distillation and rectification, each step must be optimized to ensure high purity, yield, and energy efficiency. A high-quality distillery plant reduces operational costs, minimizes waste, and ensures consistent product output �� critical for beverage alcohol, fuel ethanol, and industrial alcohol producers.

Manufacturers that offer customized solutions, integrated automation, and robust after-sales support tend to stand out in this competitive space.

Rattan Industri: A Trusted Name in Distillery Equipment

Rattan Industri has earned a strong reputation as a leading manufacturer and exporter of distillery plants in India and globally. With decades of experience and a focus on technological innovation, the company offers end-to-end solutions for molasses-based, grain-based, and cane juice-based distilleries. Their product line includes fermentation tanks, distillation columns, evaporation systems, and zero liquid discharge solutions.

The strength of Rattan Industri lies in its comprehensive engineering capabilities, customer-centric approach, and consistent focus on quality and sustainability.

Key Features That Set Rattan Industri Apart

1. Customized Plant Design: Every distillery has unique requirements based on its feedstock, production capacity, and regulatory environment. Rattan Industri excels at offering tailored plant designs to meet specific client needs. Whether it’s a greenfield project or an expansion, their engineering team ensures optimal process integration and scalability.

2. Advanced Technology: Rattan Industri incorporates the latest advancements in distillation and fermentation technology. Their continuous fermentation systems and multiple-effect distillation columns help clients achieve higher alcohol recovery with lower energy consumption. Integration of PLC/SCADA automation systems enables real-time monitoring and control for enhanced plant efficiency.

3. Energy and Water Efficiency: Environmental sustainability is at the core of modern distillery plants operations. Rattan Industri designs plants with energy-efficient boilers, heat recovery systems, and water recycling modules. Their zero liquid discharge (ZLD) systems ensure that wastewater is treated and reused, helping clients meet stringent environmental norms.

4. Robust Construction and Materials: The equipment manufactured by Rattan Industri is made from high-grade stainless steel and other corrosion-resistant materials. Their manufacturing process adheres to international standards like ASME and ISO, ensuring long-lasting performance and minimal maintenance.

5. Strong After-Sales Support: Installation and commissioning are just the beginning. Rattan Industri offers excellent after-sales services including operator training, technical support, and prompt spare parts supply. This commitment to customer service has helped them build long-term relationships with clients worldwide.

Applications Across Multiple Industries

Rattan Industri’s distillery plants cater to a wide range of industries including beverage alcohol, pharmaceuticals, biofuels, and industrial chemicals. Their ability to handle different raw materials — from molasses and grains to sugarcane juice — makes them a versatile choice for manufacturers seeking flexibility in production.

Conclusion

In a market flooded with equipment suppliers, choosing a distillery plant manufacturer that delivers both quality and reliability is vital. Rattan Industri stands out with its commitment to innovation, sustainability, and customer satisfaction. Their proven track record, global footprint, and end-to-end solutions make them a preferred partner for distillery projects of all sizes.

Visit:- https://www.liquorbottlingplants.com/distillery-plant.html

0 notes

Text

Ring Main Unit (RMU) - Adlite Electricals

Ring Main Unit (RMU) – Compact & Reliable Power Distribution

Adlite Electricals is a trusted RMU supplier in Faridabad, offering a wide range of Ring Main Units designed for high performance in 11kV medium-voltage power distribution networks. Our solutions include 1 way RMU, 3 way RMU, and advanced configurations like RMU 1 incoming 2 outgoing, ensuring flexibility for diverse applications.

We supply top-quality products from leading brands such as ABB RMU 11kV, Eaton RMU, Siemens RMU, Lucy RMU 11kV, Megawin RMU, and Crompton make RMU. Options like ABB RMU 11kV manual, Lucy RMU 11kV manual, and Crompton 11kV RMU are ideal for utilities, industrial plants, and compact substations.

Our Ring Main Units are SF₆ insulated, offering high dielectric strength and arc-quenching capability. With current ratings up to 630A and short-circuit capacities of 26.3kA, our RMUs ensure safe, maintenance-free operation. Each unit is built with load break switches, vacuum circuit breakers, and full interlocking for enhanced protection.

As a leading ABB RMU supplier in India, we specialize in delivering reliable, compact, and SCADA-ready RMUs tailored to your needs. Whether you're sourcing a Siemens make RMU, Crompton RMU supplier, or a custom-configured system, Adlite Electricals has the right solution.

🔗 Learn more: adliteelectricals.com/products/ring-main-unit-rmu

#RMU#Ring Main Unit#1 way RMU#3 way RMU#ABB RMU 11kv#ABB RMU 11kv manual#Eaton RMU#Megawin RMU#ABB RMU in supplier in India#RMU supplier Faridabad#Siemens make RMU#Siemens RMU#Lucy RMU 11kv#Lucy RMU 11kv manual#Crompton make RMU#Crompton RMU supplier#RMU 1 incoming 2 outgoing#Crompton 11kv RMU

0 notes

Text

Alarm Management Software

#Alarm Management Application#Alarm Management Software#Industrial Alarm Management Application#Industrial Alarm by SMS#OPC Alarm by SMS#OPC alarm notification software#MSSQL Backup Utility#SQL Server Backup#SQL Backup and Restore Utility#MSSQL Data Truncate#Data Backup and Restore#Database Backup#Database Backup and Restore Utility#opc alarms by SMS applications Alarms by SMS#sql alarms by SMS application#Digital Alarms by SMS#digital alarms by SMS application#Analog Alarms by SMS#analog alarms by SMS application#SMS Alarm SCADA#SMS Alarm SCADA system

0 notes

Text

AVEVA (Wonderware) System Platform

SCADA, HMI, MES, and IIoT applications, AVEVA System Platform (previously Wonderware System Platform) is a unified operations center solution that offers an open, adaptable, and scalable architecture. In manufacturing and infrastructure operations, it provides a common basis for supervisory control, data collection, and real-time display.

Key Features of AVEVA System Platform

Object-Oriented Architecture

Scalability and Flexibility

Centralized Configuration and Deployment

Real-Time Data Handling

Integrated Historian

Security and User Management

Common Use Cases

Supervisory control and monitoring for manufacturing plants.

Energy and utilities operations management.

Water and wastewater facility control.

Oil & gas SCADA systems.

Smart buildings and infrastructure monitoring.

#automation#technology#tech#plc automation#aveva#scadatraining#scada systems#software programing#software#PLC#VFD#automotive

2 notes

·

View notes

Text

Factory Automation by Servotech for Modern Manufacturing

In an era where efficiency, speed, and precision are the cornerstones of successful manufacturing, factory automation has emerged as a game-changing force. Servotech, a leading innovator in automation solutions, is at the forefront of this industrial evolution. By integrating cutting-edge technology into manufacturing workflows, Servotech is transforming traditional production facilities into smart, efficient, and highly productive environments.

What is Factory Automation?

Factory automation involves the use of control systems—such as computers, robotics, and information technologies—to operate equipment and processes in manufacturing with minimal or no human intervention. It includes everything from automated machinery and sensors to artificial intelligence and machine learning applications that monitor and optimize operations.

The Role of Servotech in Modern Factory Automation

Servotech is a trailblazer in designing and delivering customized automation systems tailored to the unique needs of modern manufacturers. The company’s solutions encompass a wide range of applications, from assembly line automation to smart data analytics, helping businesses streamline operations and improve quality standards.

By combining innovation, engineering excellence, and a deep understanding of industry-specific challenges, Servotech empowers manufacturers to stay competitive in an increasingly digitized marketplace.

Key Features of Servotech's Factory Automation Solutions

1. Advanced Robotics Integration

Servotech integrates advanced robotics into manufacturing systems to handle repetitive, hazardous, or precision-dependent tasks. These robots are capable of operating around the clock, improving productivity and reducing operational costs. Collaborative robots (cobots), designed to work alongside humans safely, are also a core offering.

2. Intelligent Control Systems

The backbone of factory automation is intelligent control. Servotech deploys PLCs (Programmable Logic Controllers), SCADA (Supervisory Control and Data Acquisition), and DCS (Distributed Control Systems) to ensure seamless communication between machines and systems.

These controls allow real-time monitoring, quick decision-making, and effective process adjustments, minimizing downtime and maximizing output.

3. IoT-Enabled Smart Manufacturing

Servotech embraces the Industrial Internet of Things (IIoT) by embedding smart sensors and connected devices within factory setups. This connectivity facilitates:

Real-time performance tracking

Predictive maintenance

Remote diagnostics

Data-driven decision-making

With IoT, factories become more agile and capable of self-optimization.

4. Custom Automation Solutions

No two manufacturing processes are identical. Servotech provides tailored automation solutions specific to the client’s industry, product type, and production scale. Whether it’s automotive, electronics, pharmaceuticals, or food processing, their systems are designed to enhance efficiency and ensure compliance with industry standards.

Benefits of Servotech’s Factory Automation Systems

1. Increased Productivity and Efficiency

Automated systems significantly reduce the time required to perform repetitive tasks. Servotech’s solutions accelerate production cycles, increase throughput, and eliminate bottlenecks.

2. Consistent Quality and Precision

Human error is a significant source of defects in manual manufacturing. Servotech’s automation ensures precision and repeatability, leading to higher product quality and reduced waste.

3. Cost Savings

Though the initial investment in automation can be substantial, the long-term cost savings are significant. Servotech’s systems reduce labor costs, minimize material wastage, and lower energy consumption through optimized processes.

4. Enhanced Safety

By automating dangerous or strenuous tasks, Servotech reduces the risk of workplace injuries. Robots and machines handle hazardous materials or high-temperature processes, ensuring worker safety and regulatory compliance.

5. Scalability and Flexibility

Modern manufacturing demands adaptability. Servotech’s modular and scalable automation systems can be easily upgraded or reconfigured to meet changing production needs or market demands.

Real-World Applications of Servotech Automation

Automotive Industry

Servotech's automation solutions are instrumental in assembling components with high accuracy, managing inventory in real time, and ensuring consistent output quality in vehicle production.

Electronics Manufacturing

Micro-level precision is critical in electronics. Servotech offers robotic soldering, PCB handling, and automated inspection systems that enhance speed and accuracy.

Pharmaceutical Production

From sterile manufacturing to packaging, Servotech ensures compliance with stringent regulatory standards while maintaining efficiency and cleanliness in pharmaceutical environments.

Food and Beverage

Automated packaging, labeling, and quality control systems from Servotech enhance hygiene, reduce spoilage, and meet diverse product specifications in the food sector.

Why Choose Servotech for Factory Automation?

1. Proven Expertise

Servotech has a strong track record of delivering reliable and scalable automation projects across various sectors. Their team comprises skilled engineers, system integrators, and industry consultants.

2. Innovative Technology

Servotech invests heavily in R&D, ensuring that their solutions incorporate the latest technologies like AI, machine vision, edge computing, and more.

3. End-to-End Support

From consultation and system design to installation, training, and after-sales service, Servotech provides comprehensive support throughout the automation journey.

4. Sustainability Focus

Servotech’s solutions are engineered to be energy-efficient and environmentally sustainable, helping manufacturers reduce their carbon footprint while improving profitability.

Future of Manufacturing with Servotech

As we move further into the Fourth Industrial Revolution (Industry 4.0), factory automation will become not just a competitive advantage, but a necessity. Servotech is committed to driving this change by providing intelligent, adaptable, and future-ready automation solutions.

In the future, we can expect:

More AI-integrated automation

Increased use of digital twins for simulation and optimization

Fully autonomous production lines

Seamless integration with enterprise-level ERP and CRM systems

Servotech is already working on these advancements, ensuring its clients are not only ready for the future—but leading it.

Conclusion

Factory automation is redefining modern manufacturing by improving productivity, quality, safety, and sustainability. Servotech stands out as a leader in this space, offering customized, cutting-edge solutions that help industries meet the demands of today and the challenges of tomorrow.

Whether you're a large-scale manufacturer or a growing enterprise, Servotech can help you transition to a smarter, more efficient production model. With their expertise, innovation, and customer-centric approach, your journey toward intelligent manufacturing begins here.

0 notes

Text

What Is PLC and SCADA? 2025 Beginners Guide

In the modern industrial world, automation is key to ensuring efficient, reliable, and safe operations. Two of the most important technologies behind industrial automation are PLC (Programmable Logic Controller) and SCADA (Supervisory Control and Data Acquisition). These systems are widely used across various industries, including manufacturing, power generation, oil and gas, water treatment, and transportation. This guide provides a clear understanding of what PLC and SCADA are, how they function, and how they work together to streamline industrial operations.

Understanding PLC: The Core of Industrial Automation

A Programmable Logic Controller (PLC) is a rugged digital computer designed specifically for controlling industrial machines and processes. It replaces traditional relay-based control systems and offers flexibility, reliability, and ease of programming.

PLCs are used to automate repetitive tasks. They receive input signals from sensors, process those signals according to a programmed logic, and then trigger appropriate outputs. These outputs can be used to control motors, solenoids, alarms, or other machinery.

One of the main advantages of PLCs is their ability to withstand harsh industrial environments. They are resistant to vibration, electrical noise, extreme temperatures, and dust, making them ideal for use in factories and processing plants.

Components of a PLC System

A basic PLC system includes the following components:

CPU (Central Processing Unit): The brain of the PLC that executes the control logic.

Power Supply: Provides the necessary voltage to the PLC system.

Input/Output Modules: Interface with field devices like sensors and actuators.

Programming Device: Used to write and transfer the logic to the CPU.

Communication Ports: Allow the PLC to connect with SCADA or other PLCs.

Introduction to SCADA: Centralized Monitoring and Control

While PLCs perform local control, SCADA (Supervisory Control and Data Acquisition) provides centralized supervision. SCADA is a software-based system that monitors and controls industrial processes from a central location.

SCADA systems collect data from PLCs and other control devices, display it in a user-friendly graphical format, and store it for future analysis. Operators can monitor equipment status, receive alarms, and send control commands from a SCADA interface.

SCADA is essential in large-scale operations where physical presence at every machine or sensor is not feasible. It allows industries to maintain control over complex systems spread across multiple locations.

Key Features of SCADA Systems

Real-Time Data Acquisition: Gathers data from field devices continuously.

Graphical User Interface (GUI): Displays process visuals for operators.

Alarm Management: Notifies operators of abnormal conditions.

Data Logging and Reporting: Stores historical data for audits and performance evaluation.

Remote Control: Enables operators to control equipment from a distance.

How PLC and SCADA Work Together

In most industrial setups, PLCs are responsible for direct control of machinery. They process sensor data and control outputs based on pre-defined logic. SCADA, on the other hand, acts as a higher-level system that collects data from multiple PLCs, analyzes it, and presents it to operators.

For example, in a water treatment plant, PLCs might control individual pumps and valves, while SCADA provides a dashboard showing water levels, chemical dosages, and system status in real-time. If there is a problem, SCADA alerts the operator, who can then take corrective action remotely.

Applications of PLC and SCADA

The combined use of PLC and SCADA systems is common in many sectors:

Manufacturing: For managing automated assembly lines.

Power Plants: For monitoring turbines, generators, and safety systems.

Water Treatment: For controlling pumps, valves, and chemical dosing.

Oil and Gas: For pipeline monitoring, storage management, and leak detection.

Transportation: For traffic signal control and railway automation.

Benefits of Integrating PLC and SCADA

Improved Efficiency: Automation reduces human error and increases throughput.

Remote Monitoring: Operators can control systems from central control rooms.

Reduced Downtime: Quick response to system failures minimizes interruptions.

Data-Driven Decisions: Real-time and historical data support informed planning.

Cost Savings: Optimized operations lower operational and maintenance costs.

Conclusion

PLC and SCADA systems are foundational technologies in industrial automation. PLCs handle the core control functions at the equipment level, while SCADA provides real-time monitoring and centralized management. Together, they create a powerful system that improves reliability, safety, and efficiency in complex industrial environments.

As industries continue to evolve with Industry 4.0 and smart technologies, the integration of PLC and SCADA will become even more critical. Understanding these systems is essential for engineers, technicians, and anyone aspiring to work in the field of automation.

#What is PLC#What is SCADA#Industrial automation#PLC SCADA tutorial#plc scada system 2025#role of plc in automation

0 notes

Text

The Role of Protection Relays in Switchgear Systems

In any electrical power system, safety, reliability, and efficiency are critical. Electrical switchgear is the equipment used to control, protect, and isolate electrical circuits and equipment. One of the most important components inside a switchgear system is the protection relay.

Protection relays act as the brain of the protection system, continuously monitoring electrical conditions and responding quickly to abnormal situations. But what exactly do they do, and why are they so important?

What is a Protection Relay?

A protection relay is an automatic device that monitors electrical quantities like current, voltage, frequency, and power. When it detects a fault or abnormal condition (such as an overload, short circuit, or earth fault), it sends a signal to the circuit breaker to disconnect the faulty part of the system.

In simple terms, protection relays help to: ✅ Detect problems early ✅ Minimize damage to equipment ✅ Prevent electrical fires and hazards ✅ Ensure continuous and safe operation

Without protection relays, a fault could go unnoticed until it causes serious damage or a complete system failure.

How Do Protection Relays Work?

Protection relays constantly compare the measured values in the system with preset limits. If these values go outside safe levels, the relay activates. For example:

If current exceeds the safe limit → relay triggers → breaker opens → fault isolated.

If a phase loses voltage → relay detects → breaker opens → equipment protected.

Modern relays can also communicate with other systems, send alarms, and store event data for analysis.

Types of Protection Relays

There are several types of protection relays, each designed for specific applications:

· Overcurrent Relays — Protect against excessive current.

· Earth Fault Relays — Detect leakage currents to earth/ground.

· Differential Relays — Monitor differences in current between two points to detect faults.

· Distance Relays — Protect transmission lines by measuring impedance.

· Directional Relays — Detect the direction of current flow for complex networks.

Older systems used electromechanical relays with moving parts. Today, most systems use digital or numerical relays, which are more accurate, reliable, and flexible.

Why Are Protection Relays Essential in Switchgear?

In a switchgear system, relays and circuit breakers work together to ensure that faults are isolated quickly and safely. Their key roles include:

🔍 Fast fault detection — Reducing the duration of faults improves safety and prevents equipment damage. ⚡ Selective protection — Only the faulty section is disconnected, while the rest of the system continues operating. 💾 Event recording and data logging — Helps engineers analyze faults and improve system reliability. 📡 Remote control and communication — In modern smart grids, relays can send status updates and alarms to operators instantly.

Without protection relays, a fault could spread and cause wider system failures, expensive repairs, or even endanger lives.

Modern Trends in Protection Relays

Today’s protection relays are more than just protection devices. They have evolved into multifunctional intelligent electronic devices (IEDs) that combine protection, control, measurement, and communication in one unit.

Some of the modern features include: ✅ Self-diagnosis and health monitoring ✅ Integration with SCADA and automation systems ✅ Programmable logic for custom protection schemes ✅ Support for IEC 61850 communication protocols

These innovations make protection relays critical for smart grids and digital substations, enabling more efficient and automated power systems.

Conclusion

Protection relays are a vital part of electrical switchgear systems, serving as guardians of safety and reliability. By detecting faults quickly and accurately, they protect equipment, prevent accidents, and ensure that electrical power systems continue running smoothly.

As power networks grow more complex, protection relays are becoming smarter and more powerful, playing an even bigger role in the future of energy management.

For engineers, technicians, and power system operators, understanding the role and functions of protection relays is key to building safer and more efficient electrical networks.

#electrical equipment#switchgear#electrical#qatar#911 abc#arcane#artists on tumblr#batman#cats of tumblr#cookie run kingdom

0 notes